Choosing the right concrete coating isn’t just about colour — it’s about durability, chemical resistance, UV exposure, and how the space will be used. At Task Master Epoxy, we use multiple professional-grade coating systems to ensure the best performance for each environment, whether it’s a residential garage, basement, warehouse, or exterior concrete surface.

Below is a breakdown of the most common coating materials we use and where each performs best.

We also meet GTA dust-control regulations by using compliant dust-collection grinding equipment—critical for commercial properties that restrict traditional grinding indoors.

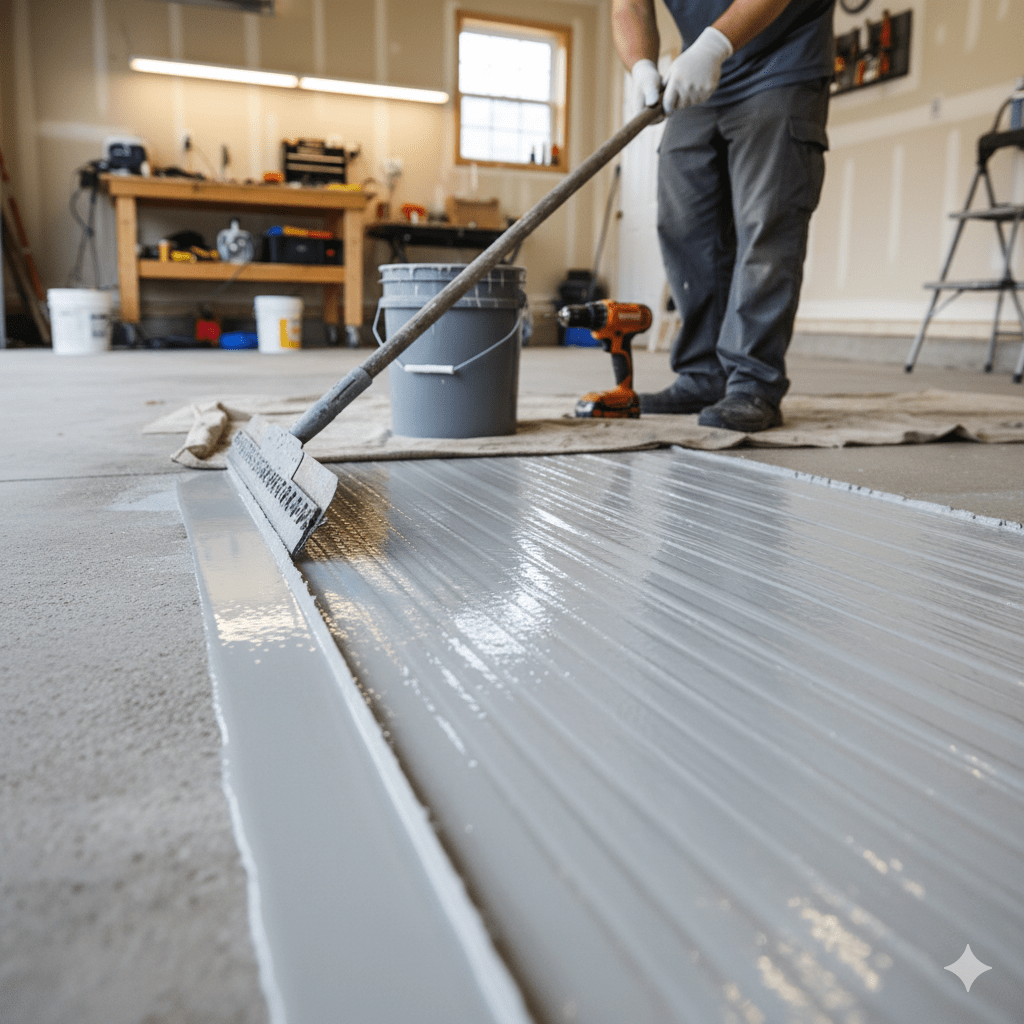

Epoxy is a two-part resin-based coating known for its strong bond to concrete and excellent durability. It’s one of the most widely used coatings for interior concrete floors.

Residential garages

Basements

Mechanical rooms

Warehouses and commercial interiors

Excellent chemical resistance (oil, fuel, cleaners)

Strong acid resistance depending on formulation

Smooth or decorative solid colour finishes

Can be combined with decorative flake systems

Cost-effective for large interior areas

Limited UV resistance — may yellow or fade when exposed to direct sunlight

Not ideal for exterior applications without a UV-stable topcoat

Interior spaces where durability and chemical resistance matter more than UV exposure.

Polyaspartic is an advanced type of polyurea coating designed for faster curing and superior UV stability. It’s commonly used in garage floors and exterior concrete.

Residential garages

Driveways & exterior slabs

Commercial spaces needing fast return to service

Superior UV resistance (won’t yellow or fade)

Rapid cure times — often installed in one day

Excellent moisture tolerance

Strong chemical and abrasion resistance

Ideal for solid colour or flake epoxy systems

Polyaspartic coatings handle sunlight, temperature changes, and moisture far better than traditional epoxy, making them ideal for Ontario’s climate.

Garages and exterior concrete exposed to sunlight and temperature fluctuations.

Polyurea is an extremely flexible and durable coating system used in demanding industrial and commercial environments. It cures very quickly and offers exceptional adhesion.

Industrial facilities

Commercial garages

High-traffic areas

Areas with concrete movement or vibration

Exceptional impact and abrasion resistance

High flexibility — resists cracking

Excellent chemical resistance

Fast cure times

Works well with flake systems

Less UV stable than polyaspartic unless top-coated

Requires professional installation due to fast cure rate

Heavy-duty applications where durability and flexibility are critical.

Urethane coatings are often used as protective topcoats over epoxy systems. They offer excellent abrasion resistance and UV protection.

Topcoats for epoxy floors

Commercial and industrial interiors

Areas requiring enhanced scratch resistance

Improved UV resistance over epoxy

Excellent abrasion and wear resistance

Chemical and acid resistance

Enhances lifespan of epoxy systems

Protecting epoxy floors and improving long-term performance.

Solid colour floor coatings offer a clean, modern appearance and are a popular choice for both residential and commercial spaces. They are commonly used in garages, basements, and commercial interiors, providing a seamless and professional finish. Available in a wide range of colours and sheen levels, solid colour systems allow property owners to achieve a customized look while maintaining durability and ease of maintenance.

Decorative flake epoxy systems combine an epoxy or polyurea base coat with vinyl colour flakes and a durable protective topcoat. This system enhances both performance and aesthetics by improving slip resistance, concealing minor surface imperfections, and creating a visually appealing, long-lasting floor finish suitable for high-traffic environments.

| Coating Type | UV Resistance |

|---|---|

| Epoxy | ❌ Low |

| Urethane | ⚠️ Moderate |

| Polyurea | ⚠️ Moderate |

| Polyaspartic | ✅ Excellent |

| Coating Type | Chemical Resistance | Acid Resistance |

|---|---|---|

| Epoxy | ✅ Excellent | ✅ Very Good |

| Polyaspartic | ✅ Excellent | ✅ Good |

| Polyurea | ✅ Excellent | ⚠️ Moderate |

| Urethane | ✅ Excellent | ✅ Good |